-

Products

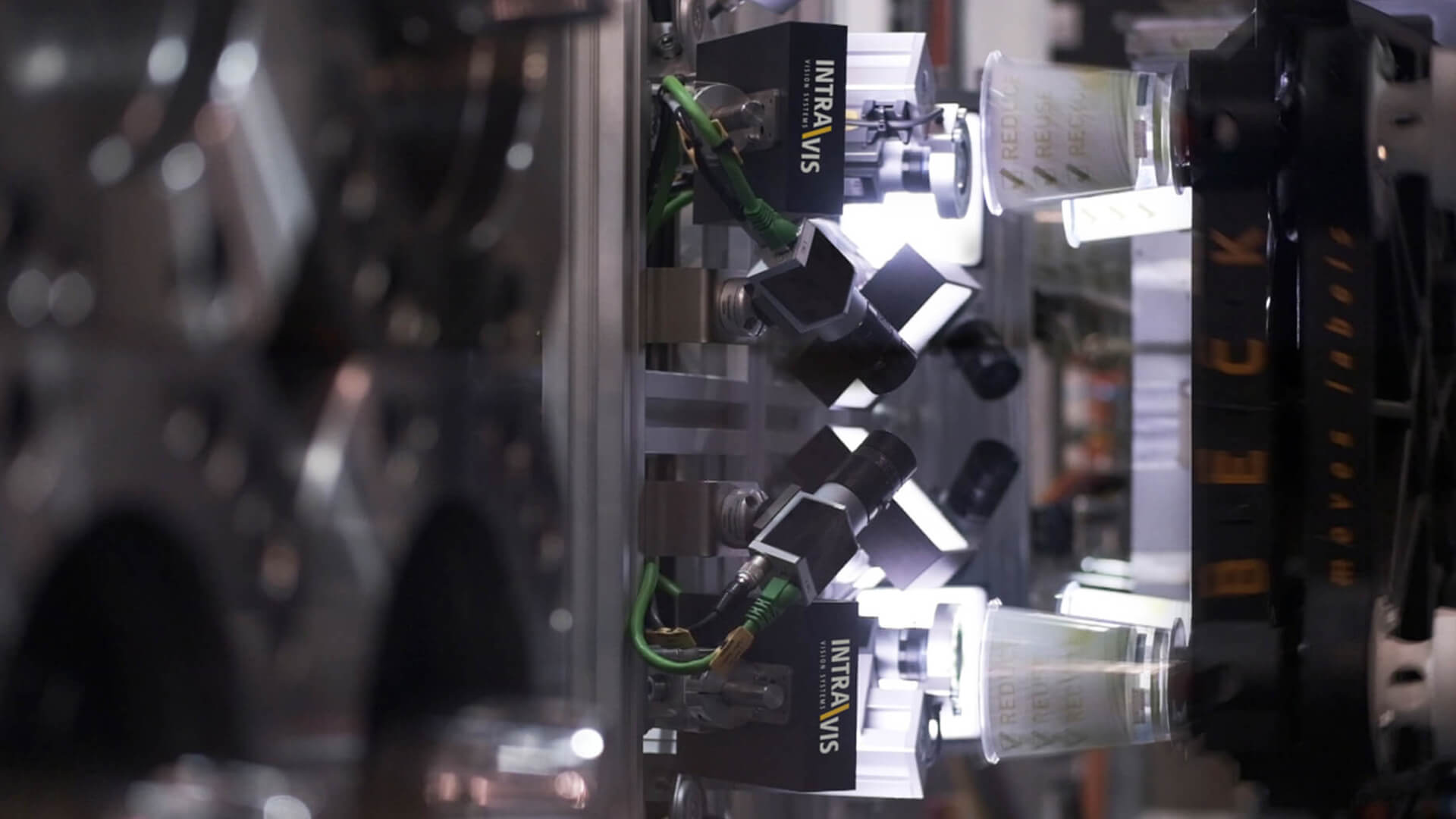

Inspection Solutions Overview CapWatcher Q-Line CapWatcher B-Line CapWatcher SC CapWatcher FC Closure periphery IntraOne BarrierWatcher

Are you Tethered Caps ready? We are.

Find out about the vision inspection of tethered caps with our CapWatcher Q-Line.

How can Artificial Intelligence and Deep Learning be used in vision inspection? In which applications is it beneficial?

- Industries

- Service

- News & Blog

- About us

- Career

- Contact

Products

Preforms

Industries

Service

News & Blog

About us

Career

Contact

Inspection Solutions Overview

PreMon

PreWatcher Offline

PreWatcher Inline

Sample-PreWatcher

LayerWatcher

ColorWatcher Lab

Caps & Closures

Inspection Solutions Overview

CapWatcher Q-Line

CapWatcher B-Line

CapWatcher SC

CapWatcher FC

Closure periphery

IntraOne

BarrierWatcher

Bottles & Containers

Inspection Solutions Overview

SpotWatcher Customized

SpotWatcher Basic

SpotWatcher Pharma

BarrierWatcher

IntraOne

Decoration & Labeling

Barrier Layer

Software