Fully automated product changeover: a massive relief in every-day life

We work every day to make our systems even more user-friendly and easier to use, because we know that: Your machine operators have little time in their day-to-day work and have to perform numerous other tasks in addition to operating the inspection system. Especially if frequent product changes are on the agenda on your production lines.

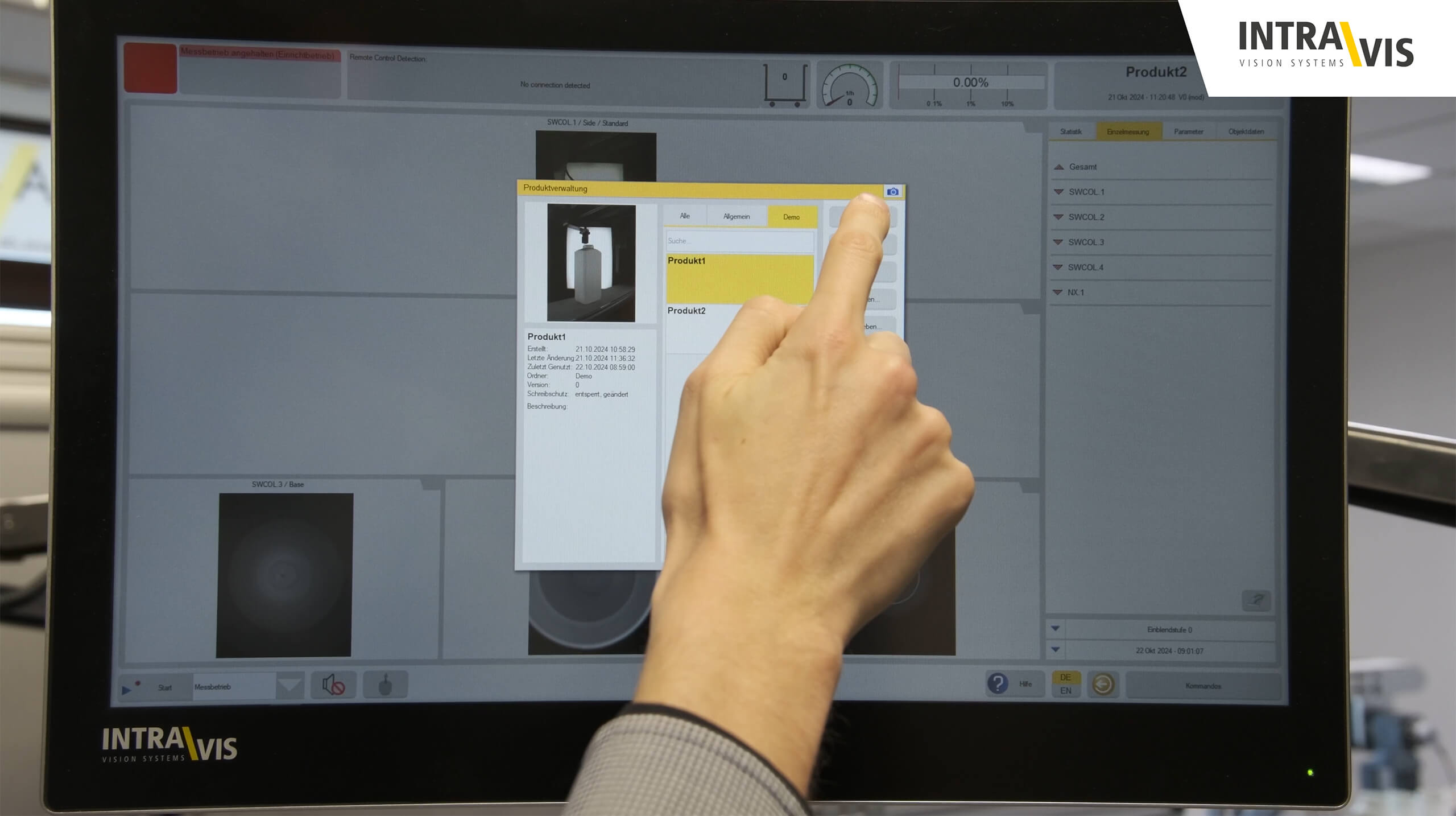

Our latest development for the SpotWatcher now takes the efficiency and user-friendliness of our inspection systems to a whole new level: the fully automated product changeover. With this feature, we offer a solution that makes product changeovers faster, easier and more reliable – at the touch of a button.

How does fully automated product changeover work?

During inspection, it is crucial that the separation, light barriers, lighting units and cameras are perfectly matched to the product to be inspected – and that they are reproducible, regardless of which operator sets up the system. This is now possible with the fully automated product changeover. Manual intervention by an operator is now a thing of the past.

A new inspection object is referenced once and its dimensions are recorded, for example by one of your employees or by one of our service technicians during commissioning or as part of a service visit. With every future product change to this referenced product, the system then adjusts all modules independently and reproducibly at the touch of a button.

The advantages at a glance

- Faster changeover to new inspection objects: Setting up the inspection system for a new inspection object only requires the push of a button. Long changeover times, where everything had to be set up manually, are a thing of the past. Production can continue within a very short time.

- Reduction of incorrect settings: The fully automated product changeover reduces the risk of human error. The risk of incorrect alignment of the separator or camera is eliminated. This means fewer rejects and more reliable inspection.

- Standardized settings, without expert knowledge: Specialized personnel are no longer required for day-to-day system settings. Automation ensures that the exact same settings and therefore precise, reproducible measurement results are achieved every time. This means that inspection is not dependent on the skills of a single operator – a massive relief in everyday life.

INTRAVIS brings efficiency and precision together

With the introduction of the fully automated product changeover, we want to support our customers in working even faster and more reliably – regardless of their employees' level of experience. At the same time, this feature ensures consistent quality and optimized processes at the touch of a button.

For more information see the video or get in touch with our sales team.